Functions of Hydraulic Oil and Reasons for Its Contamination

Introduction to Hydraulic Oil

Hydraulic Oil - Hydraulic oil is the main artery of hydraulic systems and is used as a lifeblood to operate systems smoothly. Its function is multiple—power transmission, lubrication, heat transfer and sealing. But as all liquids do, hydraulic oil can deteriorate and become dirty, or in other words, bad, which has MAJOR effects on system performance and lifespan. The article discusses the main purposes of hydraulic oil, what causes it to deteriorate, and how to reduce its adverse effects.

Functions of Hydraulic Oil

Hydraulic oil performs four main functions that are essential to the efficiency and reliability of hydraulic systems:

Energy Transmission

Hydraulic oil acts as a medium through which energy is transmitted from the pump to the hydraulic components in the system. Pressurized oil allows heavy and various machinery to work, move, respond, and be controlled at specific points.

Lubrication

The oil lubricates internal parts of the system—valves, pumps, and actuators—reducing friction and wear. This prevents early equipment failure and helps it run more smoothly.

Heat Transfer

Hydraulic oil absorbs heat generated by the mechanical parts of the system during operation. This heat is then transferred to coolers or dissipated through the system, preventing overheating.

Sealing

Hydraulic oil reduces spill in the clearances of moving parts, minimizing leakage and preserving pressure. Proper sealing ensures optimal pump performance and lowers contamination risk.

Hydraulic Oil Supply and Maintenance

Proper hydraulic oil maintenance is vital to prevent system failures and downtime. Operators can verify efficient operation by monitoring key properties such as viscosity and cleanliness. This reduces operational costs and extends component life.

Causes of Contaminated Hydraulic Oil

- Contaminants entering the system during assembly.

- Contamination of external particles entering through seals or breather caps.

- Oxidative or thermal degradation of oil.

- Internal parts breaking down and producing junk.

Types and Sources of Contamination

Contamination can be classified into four main categories:

Built-in Contamination

This kind of pollution occurs in the production and assembly process. This encompasses metal fillings, dirt and other particles that remain inside the system's building blocks.

Natural Contamination

This happens because with time, dust, dirt, and humidity enter the system, in which case, we would recommend cleaning between the LCD and your portable computer.

Ingressed Contamination

During operation, worn seals, areas where airflow has to enter the system from outside into the system, i.e, a faulty breather cap, etc, introduce contaminants into the system.

Generated Contamination

These are contaminants that arise during the operation of a system through wear or chemical reaction. Common types include:

- Abrasive Wear: Hard particles abrade the surfaces of components.

- Exfoliation: This occurs as fluid voids collapse, causing the surface to erode.

- Fatigue Wear:Multiple cycles of loading lead to spalling in the damaged area.

- Erosive Wear:Impingement of fast-moving fluid particles causes erosion of surfaces

- Adhesive Wear: The oil film is ruptured, leading to metal-on-metal contact.

- Corrosive Wear: It is caused by chemical contamination or the presence of water, resulting in rust and degradation of the surface.

Impact of Contaminants on Hydraulic Systems

Then the contaminants are injected into the body, which can have some dire consequences:

- Higher stress on the parts.

- Lower operating and capacity throughput.

- Friction leads to higher energy consumption

- The reduced life of the equipment.

- Increased downtime and timely breaks now verify more.

Like, Comment, Share this article to spread awareness and sensitize the reader to Zero Mechanical Breakdown.

Best Practices to Prevent Hydraulic Oil Contamination

- Always use good quality oil: Ensure you have a great quality (matching) oil.

- Monitor Seals: Check and change old seals to keep dirt from getting in.

- Install Filters: In Place Use the right filters for separating particles and oil cleanliness.

- Check Oil Condition: Check the oil for contamination, viscosity, and darkness as a regular process.

- Flush System Before Use: The system should be thoroughly flushed prior to putting in a fresh charge of oil.

- Reduce Exposure:Do not open the system unnecessarily to outside contaminants.

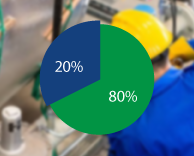

How Filtration Works in the Maintenance of Hydraulic Oil

Filtration is an essential process for maintaining the cleanliness of hydraulic oils. With advanced filtration systems capable of removing even 3-micron particles, the oil itself can remain unaffected with no risk of damage from contaminants. Minimac Systems has various Filtration solutions for different hydraulic systems that significantly increase the lifetime of the equipment and enhance efficiency.

How to Identify Hydraulic Oil Contamination

Although the vast majority of contaminants are microscopic and not visible to the human eye, contamination can sometimes present itself in other ways:

- Change in oil color or odor

- Higher operating temperatures.

- Unexpected behavior of the system or lower performance

- Noticeable particles in the oil.

While most contaminants are microscopic, routine oil analysis helps determine contamination levels and enables timely corrective actions.

Conclusion

Fluid is the heart of every hydraulic system, but is it the

backbone role of hydraulic oil, a must-have key component as

energy transmitters, lubricants, heat dissipators and sealants as

well. But contamination is the worst enemy of its functioning,

life. A deep understanding of the origin & nature of

contamination, and its effect on system performance, is the

foundation for effective maintenance.

With best practices in place a good oil, effective filtration

systems, and regular oil analysis, contaminant risks are

minimized and system reliability can be ensured. Minimac Systems

acts as a guiding hand in hydraulic oil maintenance and provides

precision information and equipment to ensure that your systems

maintain optimal working order.

Maintaining hydraulic oil is essential for hydraulic system

performance and integrity. Operators can save money, reduce

downtime, and prolong the life of the equipment by making sure

they understand what hydraulic oil does, why it gets contaminated,

and how it can be prevented from becoming contaminated.

Learn more about our services and industry insights by visiting

our official LinkedIn page:

Minimac Systems