Reclamation of FRF

A 1200 MW coal-fired thermal power plant using Indo-Chinese Turbine EHC System in Southern India

Synopsis

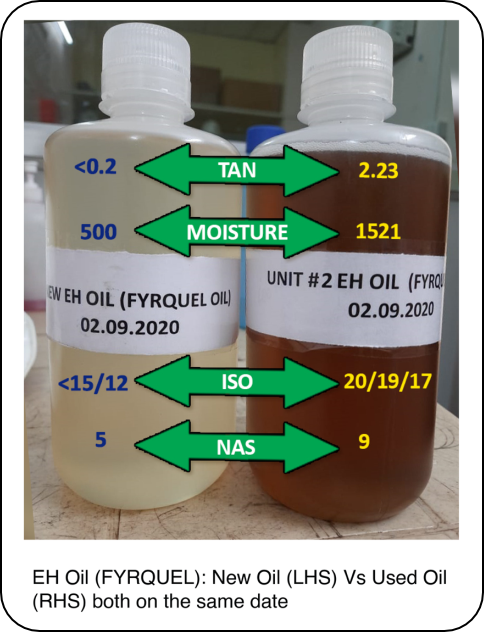

The Power plant was suffering from loss in electricity generation for a few days as per the desired target. The O&M team has identified that the turbine command is not functioning properly and was tripping frequently. On further investigation, it was found that the Servo Valve (Moog valve) has failed and showing hunting or sluggish behavior. Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” acted as a rescuer for the plant and saved the plant from an unexpected shutdown. If this system would have implemented earlier, a loss of more than 5 Cr could be saved.

Problems

Failure of Moog valve: This was the main reason for the trip of the turbine and breakdown in the power plant.

Poor Oil Analysis Program: An oil analysis is supposed to be done monthly for Particle count & TAN (weekly if the trend is negative) and weekly test for water content but the customer has scheduled these indefinitely.

Inadequate Operation Practices: The solenoid valve of the LVDH (oil purification machine) vacuum line was only 20% closed which failed to generate vacuum.

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20”comprehensively designed with 4 major technologies to • Remove solid contamination from oil by Superfine filtration. • Remove moisture from oil by Vacuum Dehydration technology. • Reduce Total Acid Number (TAN) by Ion exchange technique. • EHC system tank moisture removal and ingress prevention by Inert Gas Blanketing technique. Along with equipment installation, our Service Engineer trained the customer’s team on the function of the EH oil Re-Conditioner, FRF maintenance, contamination control and importance of the Oil Analysis Program.

Benefits

1) Extended oil life 2) Reduced TAN value 3) Elimination of oil Replacement cost 4) Protection of Turbine against hunting 5) Increased Turbine reliability.

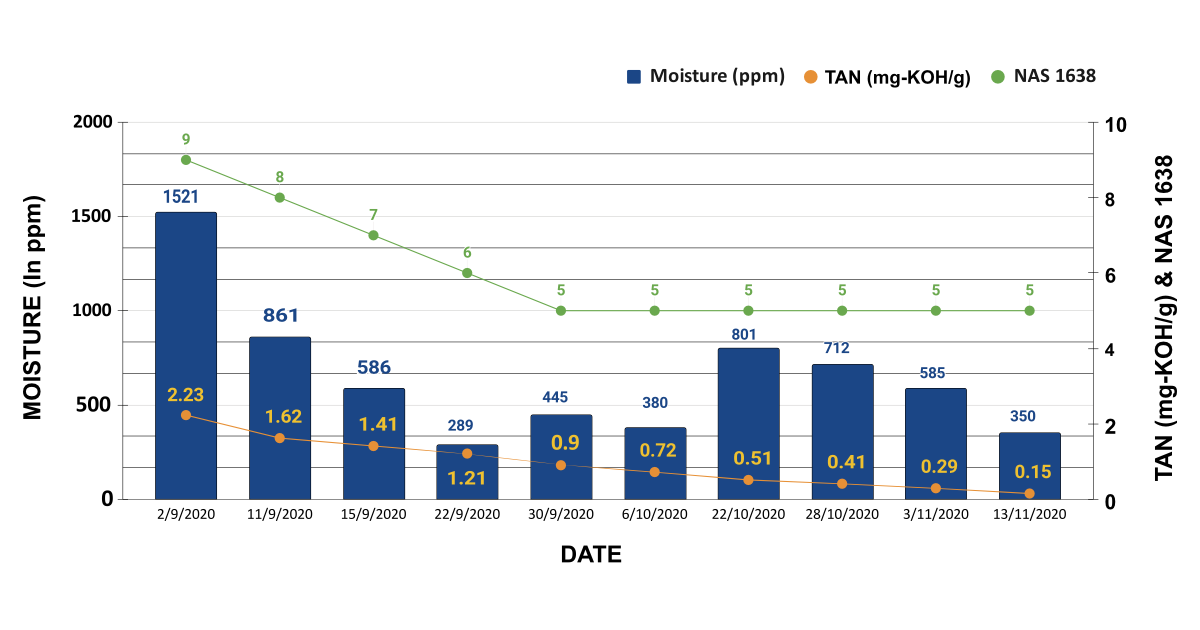

The above graph is showing the trend of decrease in the values with continuous cycling of EH Oil. Consumable Details: Filter consumption- 01 qty of 10-micron filter element and 01 qty of 3 microns consumed to achieve NAS 5 cleanliness. Total consumption of Resin- 36 Ltr. Total running hours of equipment: 698 hrs.

Subscribe to our YouTube Channel and be a part of our Journey - Click Here