Minimac accepted the challenge to filter 72 kiloliters of Oil within 72 hours

Success is FUELED by Challenges and Problems. One example of a thermal power plant, the UMPP (Ultra Mega Power Project) 2*800MW, had to deal with such a challenging problem.

An early shutdown of the unit in the 2021 plant is called an annual shutdown. During start-up, they found oil quality is not up to mark to circulate in the system. After cleaning 72 thousand liters of Oil, it was essential to operate the plant within 3 to 4 days to keep quality as per standard. The head of maintenance of the unit looked up to find a reliable and trustworthy name in the market for the work and then approached Minimac Systems Pvt. Ltd. for the rescue.

Manufacturer & Supplier of Oil Purification & Reconditioning Plants, Allied Machinery, & Laser Particle Counters. So the Minimac team took on the challenge – 72 hours to filter 72 kiloliters of Oil. It was a huge challenge, with the team familiar with its capabilities, but to drive the machine to the site and do the job on time was a big provocation. They sent the machine via truck and ultimately towed it with their own trucks. The installation took 8 hours, and they were thus prepared to hit the milestone.

Subscribe to our YouTube channel for technology updates and Free Webinars: Click here Click here

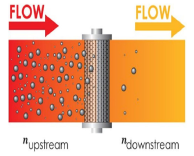

Before filtering the oil, they tested the oil and it proved to be

NAS10. Every 18 hours, oil samples were being monitored for the

work in progress. After the quality test was carried out for 3

characteristics, the Minimac team succeeded in targeted achieved

in favorable result NAS value at NAS6. Next, the machine was

executed until it reached the NAS5. Minimac completed the job in

only 40 hours – well under the 72-hour maximum time allowed for

Project 2.

Considering the enormity of the task, filtering 72K liters of oil

in 40 hrs from a compact-sized filtration trolley was nearly a

kind of world record set by the team.

The use of the correct filter on the first try, to meet that goal,

is an MR series filter element. We achieved a better result

in meeting 2X FS-150-2S-H-V with 2X FS-150-2S-H-V for good client

satisfaction.

When we take the challenge with a lot of zeal and passion, then

nothing is impossible. This synergy was made possible due to the

right mix of science and technology. It was a task to complete the

task in the time limit, yet as it is said and we might not have a

prize motto, but we believe "hard work always pays off".

Minimac wants to revolutionise the way lubrication is being done

in the industrial plants of core sector units. Zero Mechanical

Breakdown: Rotating Equipment and Hydraulic Equipment, Lubrication

Management to improve machine efficiency and preventive

maintenance, with parking costs less for Packers.

So, get in touch with our experts Today to maximize the operational life of your Equipment – Drop an Inquiry