Oil reconditioning project for India’s largest coal-based power producer

Team Minimac successfully executed a critical project to recondition the control fluid (two tanks of capacity 16 kiloliter each) for India’s largest energy conglomerate and coal-based power producer with a capacity of 4760 MW.

Synopsis

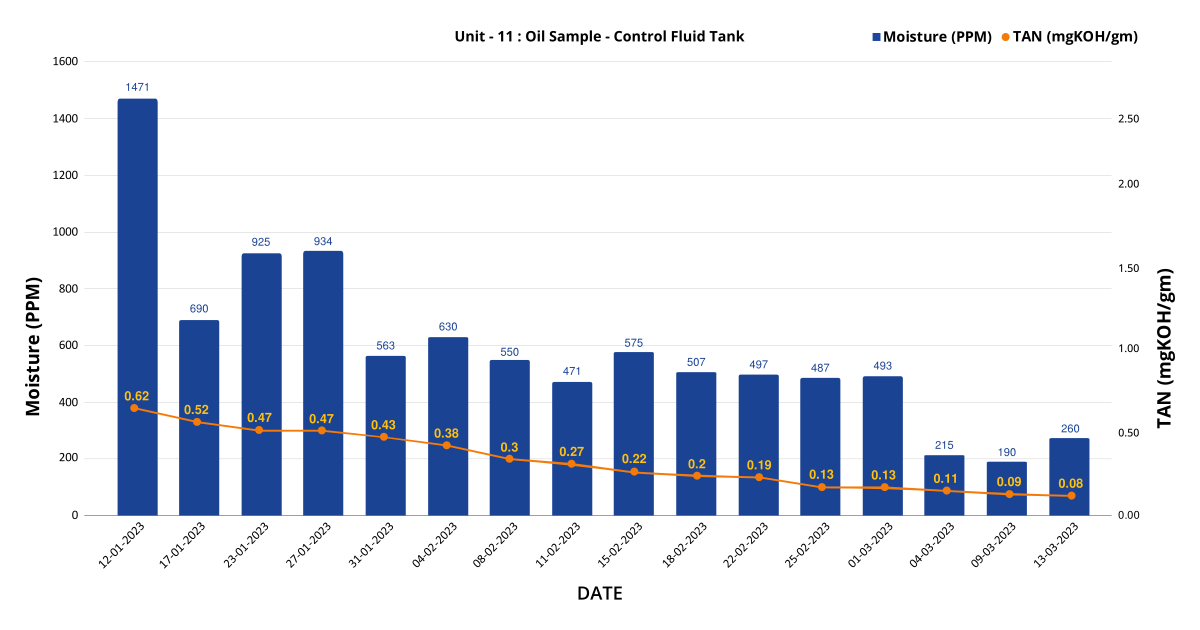

The plant was built and is in service as a thermal power generating station, in Vindhyachal. There was a problem with higher Total Acid Numbers (TAN), observed typically when moisture content exceeds the permissible range. They were facing difficulties in stable unit operation because of the sluggish and erratic behavior of the turbine governing system. It was a significant threat to unit outage and generation loss. The situation was examined by Minimac Operations and Maintenance Service (MOMS). Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL was deployed to address the issue.

Before Oil purification, the TAN value was≥ 0.62 mgKOH/gm, NAS ≥ 8, and Moisture ≥ 1471 PPM. After Oil purification, the recorded parameters were TAN value = 0.08 mgKOH/gm, NAS ≤ 4, and Moisture ≤ 260 PPM. The major challenge faced during the execution was if we charged resin, TAN would reduce, but moisture would increase. So, an analysis was done and implemented to control the moisture first, then charged the second resin cycle. Minimac gave a 100% customized and balanced solution within time.

Problems

The tank capacity was 16 kiloliters, which is huge. The biggest challenge was to execute the project while the system was in operation. Water contamination bubbles were forming, leading to the fluctuation in NAS - as for moisture control, it was necessary to turn off the system. Resin charge in Ion exchange was done intermittently to control moisture increase, and our motto was to hold moisture below 500 PPM so we could plan for the next cycle of resin charge.

Client’s Requirement

- To purify the control fluid.

- To reduce the TAN value from 0.62 to < 0.10 mgKOH/gm.

- To bring down the moisture level < 500 PPM.

- To achieve NAS < 5.

- Smooth and timely execution without any downtime.

- Tailor-made solution.

- No oil loss because of processing or spillage.

Solutions

- Resin skid - Minimac- FS-20-TRIX- 8-25 ltr-1S-FRF-DOL for NAS & moisture reduction was installed.

- Before the oil conditioning process, the TAN ≥ 0.62 mgKOH/gm, which was reduced after oil purification to TAN ≤ 0.08 mgKOH/gm.

- The Nitrogen generation unit (TMR 100) was deployed and installed at the client’s site.

- For further improvement in TAN, the oil vapor extraction fan (OVEF) was throttled in the range of 70%, with the support of the user.

- Minimac provided trained manpower and other consumables under the MOMS (Minimac Operations and Maintenance Service) offering. Minimac had given results far better than the KPIs.

Cost Saving

This plant managed to save:

- Cost of oil replacement: ₹ 3.2Cr. approx/ $ 32 Million approx

- Cost of downtime: ₹ 3.15 Cr. approx/ $ 31.5 Million approx

By investing ₹ 21 lakh approx/ $ 25.65k approx only.

CO2 e Saving

1,92,000 kg of CO2 e / 0.192 gigagrams of CO2 e

Benefits

- Extended in-service oil life.

- The smooth functioning of the machines.

- Elimination of new oil replacement cost.

- Avoiding the risk of fire and explosion.

- Reduction in the possibility of product degradation due to blanketing.

Subscribe to our YouTube Channel and be a part of our Journey - Click Here