PE fluid reconditioning in turbine EHC system

A 1,320 MW (2 x 660 MW), one of the first and largest supercritical coal-fired power plants using Indo-Chinese turbine EHC system in northern India

Synopsis

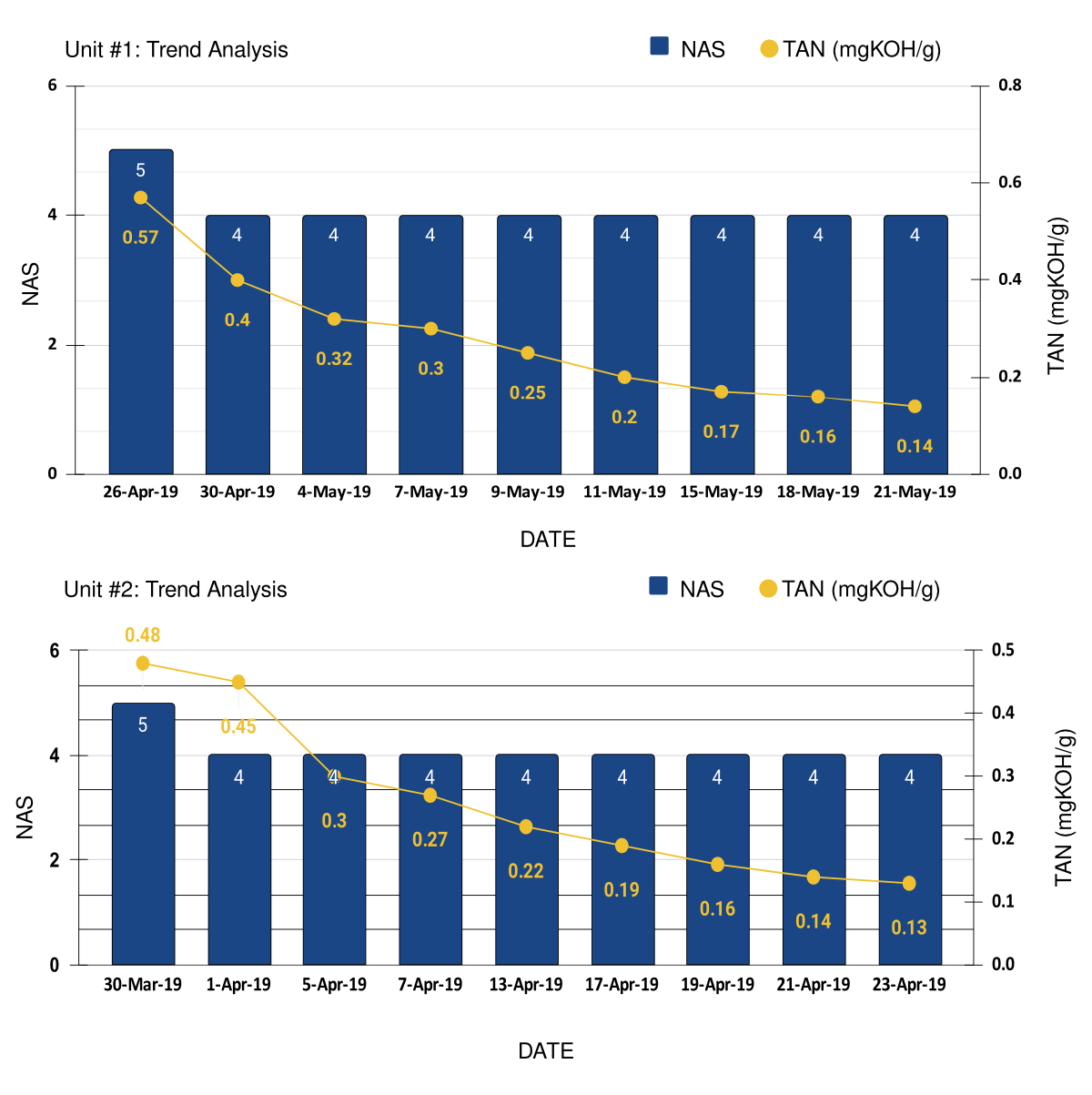

The plant was struggling with the rapid increase in TAN values in the EH oil of the governing system of the turbine. Moisture content was also more than permissible limits. Degradation of the oil was due to contamination ingression into the system resulting in by-product formation.

Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” acted as a savior for the plant and as a result the unexpected shutdown of the turbine worth ₹1.4 Cr per day was saved.

Problems

- Degradation of EH oil properties at both the units of the plant.

- The installed regeneration system for each EHGC tank of unit #1 and #2 was failing to control neutralization number (TAN value) and showing a rapid increase in the same

- The company was unaware of the consequences of increased TAN values like possibilities of failure of servo valve, hunting, power generation loss, unplanned shutdown, etc

Solutions

Installation of Minimac’s EH oil reconditioning system “MLC LVDH TRIX 20” comprehensively designed with 4 major technologies to:

- Remove solid contamination from oil by Superfine filtration

- Remove moisture from oil by vacuum Dehydration technology

- Reduce Total Acid Number (TAN) by Ion exchange technique.

- EHC system tank moisture removal and ingress prevention by Inert Gas blanketing technique.

Along with equipment installation, our service engineer trained the customer’s team on the functions of the EH oil re-conditioner, FRF maintenance, contamination control, and importance of the oil analysis program.

Cost Saving

This plant managed to save:

- Cost of oil replacement: ₹78 Lakh approx.

- Cost of downtime: ₹5.6 Cr approx

CO2 e Saving

14,400 kg of CO2 e / 0.0144 gigagrams of CO2 e.

Benefits

- Extending oil life.

- Eliminate oil Replacement cost.

- Protect Turbine against hunting.

- Increased Turbine reliability.

Subscribe to our YouTube Channel and be a part of our Journey - Click Here